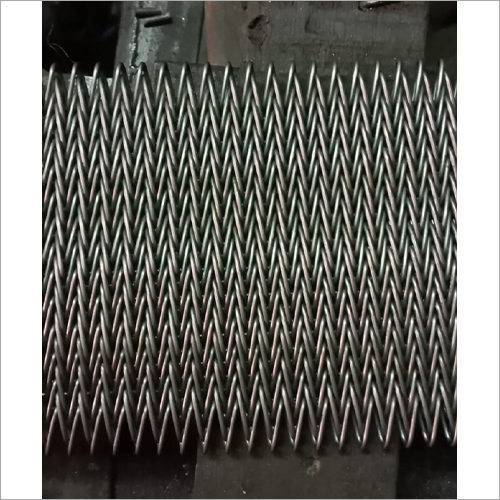

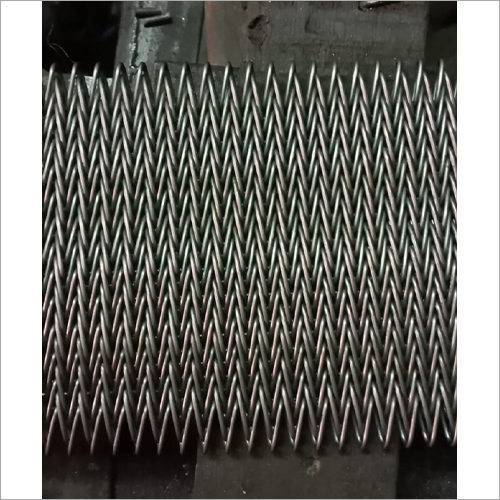

- Balanced Weave Belts: A series of wire spirals connected by a crimped rod, offering straight tracking and good stability.

- Flat Wire Belts: Made with flat wire spirals, suitable for applications requiring a smooth surface.

- Woven Wire Belts: Constructed from woven wire, offering flexibility and durability.

Advanced Industrial DesignCombining the strength of chain conveyors with flat belt efficiency, our wire mesh conveyor belt is engineered for demanding industrial environments. The live powered roller and dilute-phase pneumatic system facilitate rapid transport with minimal product damage, making them suitable for manufacturing, packaging, and assembly operations in various sectors.

Reliable Vertical HandlingThe integrated reciprocating vertical conveyor ensures safe and seamless movement of products between different elevations. This vertical solution optimizes factory layouts, reduces manual handling, and boosts overall operational efficiency by automating the vertical transfer of goods within industrial facilities.

FAQs of Wire mesh conveyor belt:

Q: How does the wire mesh conveyor belt improve material handling for industrial usage?

A: The wire mesh conveyor belt combines chain structure, flat belt, and powered rollers, enabling smooth, continuous movement of industrial materials. Its design ensures reliable transport for both horizontal and vertical movement, minimizing manual intervention and increasing process efficiency.

Q: What is the function of the reciprocating vertical conveyor in this system?

A: The reciprocating vertical conveyor facilitates the elevation of materials between different factory levels. It automates vertical movement, enhancing productivity by safely transporting goods up or down, thereby streamlining multi-level operations in industrial setups.

Q: When should industries use this wire mesh conveyor belt configuration?

A: Industries should choose this conveyor belt when handling diverse loads that require both horizontal and vertical transport, or when high throughput and minimal downtime are critical. It is ideal for manufacturing, packaging, and assembly lines where flexibility and reliability are key.

Q: Where is this wire mesh conveyor belt primarily manufactured and supplied?

A: This conveyor belt is manufactured, supplied, and traded in India. Our company offers reliable support nationwide, catering to industrial facilities needing durable and customizable conveyor solutions for their unique operational requirements.

Q: What is the benefit of the dilute-phase pneumatic conveying system within the belt structure?

A: The dilute-phase pneumatic conveying system enables fast, gentle movement of lightweight goods, reducing product degradation and ensuring efficient, unobstructed material flow. It is particularly beneficial in handling bulk powders and granular products.

Q: How does the chain structure enhance the durability of the conveyor belt?

A: The chain structure strengthens the belt and provides high load-bearing capacity, making it suitable for heavy-duty applications. It ensures consistent performance even in harsh industrial environments, offering longevity and reduced maintenance costs.

Q: What process is involved in customizing the wire mesh conveyor belt for specific industrial needs?

A: Customization involves assessing the clients operational requirements, selecting the appropriate conveyor type, belt configuration, and system features. We collaborate closely to deliver tailored solutions that meet distinct material handling challenges faced by different industries.

![]() GST No.19ABSFA5687N1ZB

GST No.19ABSFA5687N1ZB