MS Wire Mesh Conveyor Belt Price & Specifications

Vertical Conveyor Reciprocating Vertical Conveyor

Usage Industrial

Type Chain Conveyor

Structure Chain

Roller Conveyor Live Powered

Resistant Feature Oil Resistant

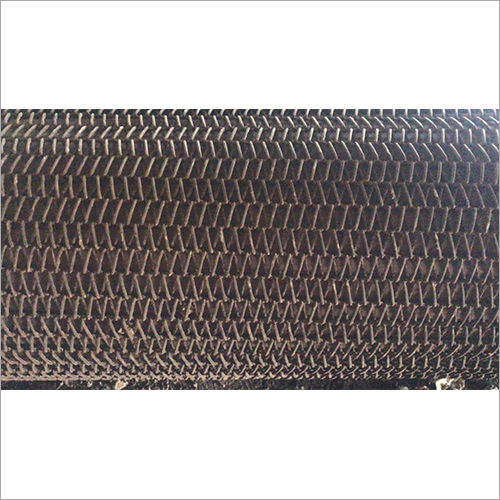

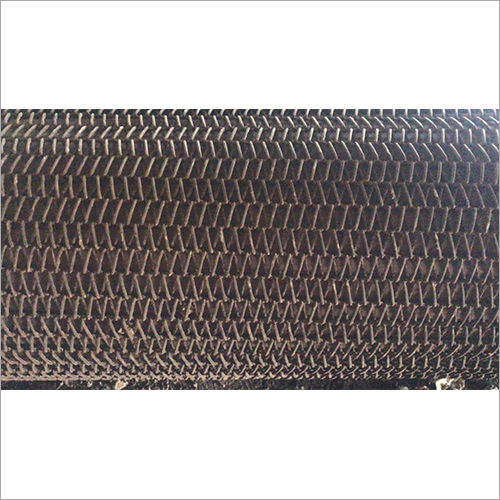

Product Type MS wire mesh Conveyor Belt

Pneumatic Conveyor Dilute-Phase

Material Matal based

Load Capacity 10000 Kilograms (kg)

Color White

Belt Conveyor Flat Belt

Supply Ability 400 Per Month

Sample Available No

Payment Terms Cash in Advance (CID)

Main Export Market(s) Asia

Main Domestic Market All India

FOB Port kolkata

Delivery Time 10 Days

About MS Wire Mesh Conveyor Belt Detail

INDUSTRIES

A stainless steel wire mesh conveyor chain is a type of conveyor belt made of interconnected stainless steel wires, designed for efficient and reliable material handling, particularly in applications requiring high temperatures, heavy loads, or exposure to liquids. These belts are typically driven by chains on either side, with cross rods connecting the chains and supporting the meshEngineered for Heavy-Duty ApplicationsOur MS Wire Mesh Conveyor Belt is built to handle up to 10,000 kilograms, making it ideal for heavy industrial operations. The chain structure and reinforced metal mesh offer superior strength and stability, ensuring continuous operation even under rigorous conditions. The white color finish not only adds a clean appearance but also enables easy inspection and maintenance.

Multi-Functional & Adaptable DesignThis conveyor system combines flat belt and chain conveyor capabilities, along with a reciprocating vertical conveyor for vertical transport. The inclusion of a dilute-phase pneumatic component and oil-resistant properties ensures smooth processing of diverse materials, reducing both downtime and maintenance costs.

FAQs of MS Wire Mesh Conveyor Belt:

Q: How is the MS Wire Mesh Conveyor Belt typically used in industrial settings?

A: The MS Wire Mesh Conveyor Belt is primarily used for transporting heavy loads and materials across various industrial processes. It is suitable for assembly lines, material handling, and vertical movement tasks due to its robust construction and load capacity.

Q: What benefits does the oil-resistant feature offer for this conveyor belt?

A: The oil-resistant feature safeguards the belt from damage caused by oils or lubricants common in industrial environments, extending the lifespan of the conveyor and minimizing maintenance requirements.

Q: When should a reciprocating vertical conveyor be used?

A: A reciprocating vertical conveyor is essential when materials need to be transported between different vertical levels efficiently, such as between floors or platforms in a factory, while maintaining payload integrity during the process.

Q: Where can MS Wire Mesh Conveyor Belts be installed?

A: These belts are versatile and can be installed across various industrial setups, including manufacturing plants, warehouses, and processing facilities throughout India, wherever heavy-duty material transport is required.

Q: What is the typical process for installing and commissioning this conveyor belt?

A: Installation involves securely anchoring the chain and belt system, connecting electrical and pneumatic components, and calibrating the reciprocating vertical conveyor to handle specified loads. Commissioning concludes with safety and performance checks.

Q: How does the dilute-phase pneumatic conveyor function in this system?

A: The dilute-phase pneumatic conveyor uses compressed air to transport light, bulk materials rapidly along the belt, supporting the movement of items that may not be suitable for mechanical transfer alone.

Q: What are the main advantages of choosing a metal-based conveyor belt in white color?

A: A metal-based belt enhances durability under heavy loads, while the white color allows for easier detection of contamination and ensures the system meets hygienic requirements in certain industries.

![]() GST No.19ABSFA5687N1ZB

GST No.19ABSFA5687N1ZB