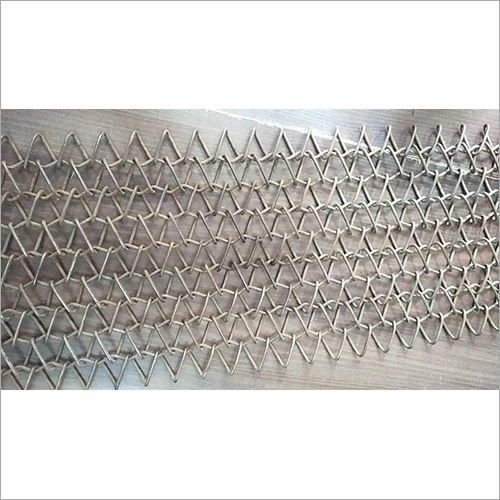

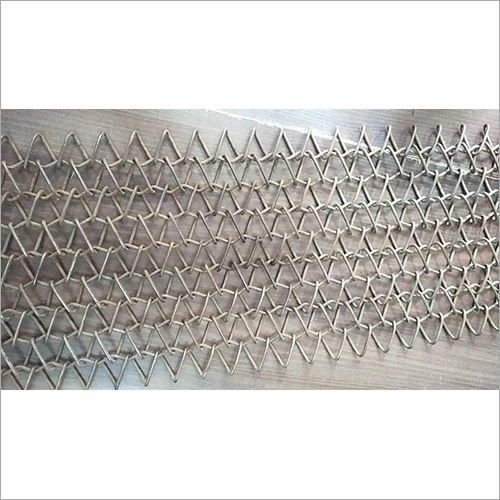

A Balanced Weave Conveyor Belt is a type of metal conveyor belt known for its straight tracking and versatility. Its constructed from a series of left and right-hand wire spirals connected by a crimped rod, creating a balanced weave pattern. This design provides good product support and stability, making it suitable for a wide range of applications, particularly in food processing and other industries requiring smooth, reliable movement of materialsAdvanced Material Handling for Evolving IndustriesWith its innovative vertical lift and live powered roller system, the Balanced Conveyor Belt with Vertical Conveyor offers unparalleled flexibility for factories and warehouses in India. Its steel construction ensures strength and low maintenance, while the flat belt design allows for the safe conveyance of varied items. The integrated pneumatic dilute-phase system provides gentle material handling, minimizing damage and boosting operational efficiency.

Exceptional Durability and Reliable PerformanceBuilt from high-quality steel and assembled with precision, this conveyor is engineered for demanding environments. Whether integrated in manufacturing, logistics, or warehousing, its chain-driven vertical structure and power-assisted rollers guarantee consistent, reliable service. The white finish provides a clean, modern appearance, complementing contemporary industrial spaces.

FAQs of Balanced Conveyor Belt:

Q: How does the vertical lift function in this conveyor system?

A: The vertical lift mechanism in this conveyor system uses a chain-driven structure to move the flat steel belt, allowing materials to be transported efficiently between different levels within a facility.

Q: What materials can be transported using this balanced conveyor belt?

A: This conveyor is suitable for a wide range of materials, including packages, bulk goods, and delicate items, thanks to its flat steel belt and dilute-phase pneumatic system for gentle handling.

Q: When is it beneficial to use live powered roller conveyors in an operation?

A: Live powered roller conveyors are advantageous when you require automated, consistent movement of goods. They are ideal for high-volume material transfer, sorting, and assembly line operations.

Q: Where can this conveyor system typically be installed?

A: It can be installed in various industrial settings such as manufacturing plants, warehouses, distribution centers, and other facilities requiring vertical and horizontal material movement.

Q: What is the process involved in installing and commissioning this conveyor?

A: Installation involves assembling the steel frame, installing the flat belt and vertical lift chain system, connecting powered rollers, and integrating the pneumatic dilute-phase equipment. Commissioning includes alignment, testing, and safety checks.

Q: How does the dilute-phase pneumatic feature contribute to the system?

A: The dilute-phase pneumatic system accelerates light materials through the conveyor, reducing the likelihood of product damage and supporting rapid, efficient movement in high-throughput environments.

Q: What benefits do manufacturers, suppliers, and traders in India gain from this conveyor?

A: They benefit from improved automation, reduced labor costs, increased productivity, and the ability to handle a diverse range of products with minimal maintenance due to the robust steel construction and advanced conveyor features.

![]() GST No.19ABSFA5687N1ZB

GST No.19ABSFA5687N1ZB