Conveyor Belt

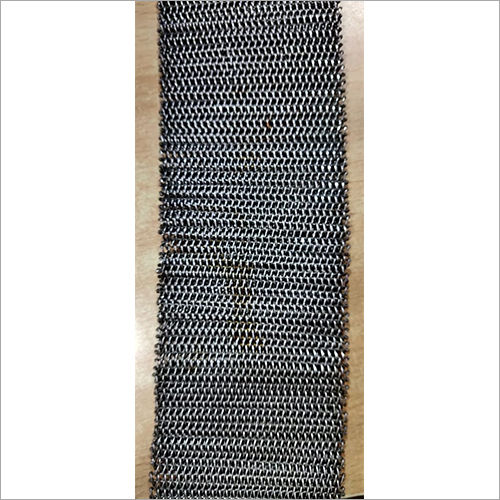

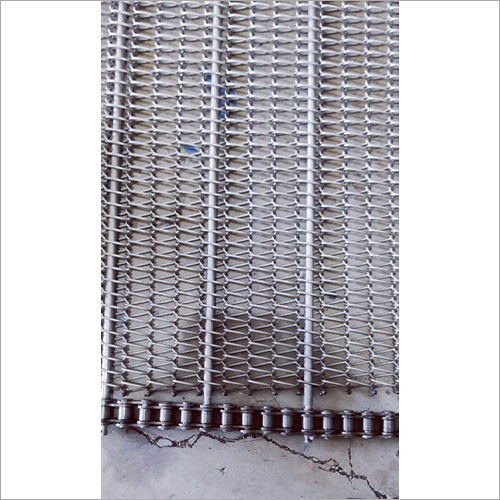

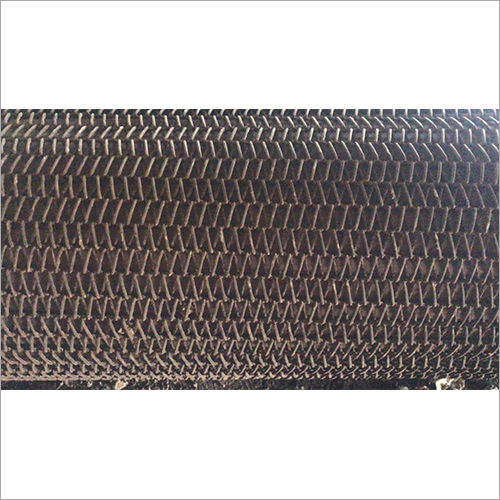

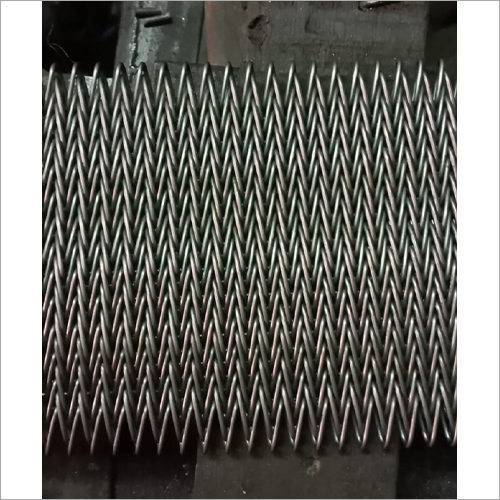

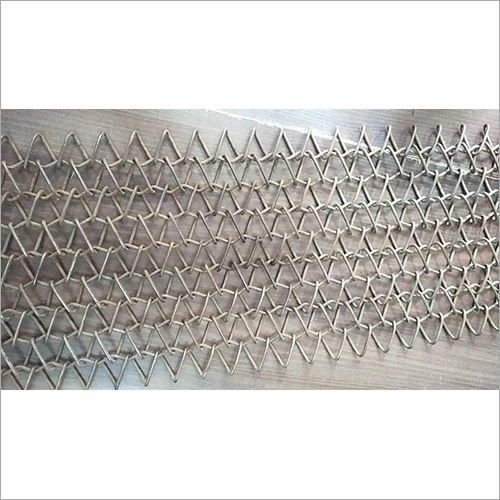

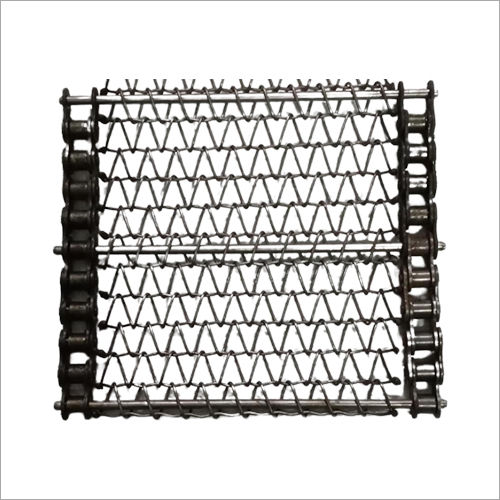

(13 products available)Unlock the advantages of our Conveyor Belt, designed and manufactured with supreme precision to meet the dynamic needs of your industrial processes. Our collection includes top-rated Wire Mesh Conveyor Belt, Stainless Steel Fine Conveyor Belt, Stainless Steel Wire Mesh Conveyor Chain, MS Wire Mesh Conveyor Belt, and Wire Mesh Conveyor Belt, offering a perfect solution for seamless transportation tasks. Experience immaculate performance with these conveyor belts, which are crafted using highly durable materials such as stainless steel and MS wire mesh to ensure longevity and reliability. As a manufacturer, supplier, and trader with over 6.0 years of expertise, we deliver the best price while maintaining impeccable quality standards. Featuring high heat resistance, unparalleled load-bearing capacity, easy maintenance, smooth operational efficiency, and a supreme ability to withstand corrosive environments, these conveyor belts are truly a must-have for industries ranging from food processing to heavy-duty manufacturing. With supply ability spanning across All India and export capabilities to Asia, our conveyor belts provide versatility and operational excellence for diverse applications. Choose our conveyor belts for the perfect balance of advanced technology and top-tier functionality that sets industry benchmarks, making them an indispensable asset for enhancing your productivity and efficiency.

Our Products

Our Products